The Ultimate Guide to Closed-Cell Foam for Sprinter Van Builds: Roof Rails, AC Units & Waterproofing

🎧 Prefer to listen? Here’s the podcast version of this article. Press play below.

Why Closed-Cell Foam Matters in Van Conversions

Closed-Cell foam is an important material for Sprinter van conversion, RV’s, and construction. It provides a cushion for roof rails, Maxxair fans, and AC units, among other things. It creates an air-tight barrier between the Sprinter van and the component. Installed correctly, this makes the component waterproof, dampens vibrations, and protects the device.

For example, when installing the Velit 2000R AC on the Sprinter van, we used a closed cell foam between the van and the AC which provides a cushion and creates an air-tight barrier. Without this, the AC plastic would be directly sitting on the metal causing major scratches and tons of gaps for air and water to sneak through.

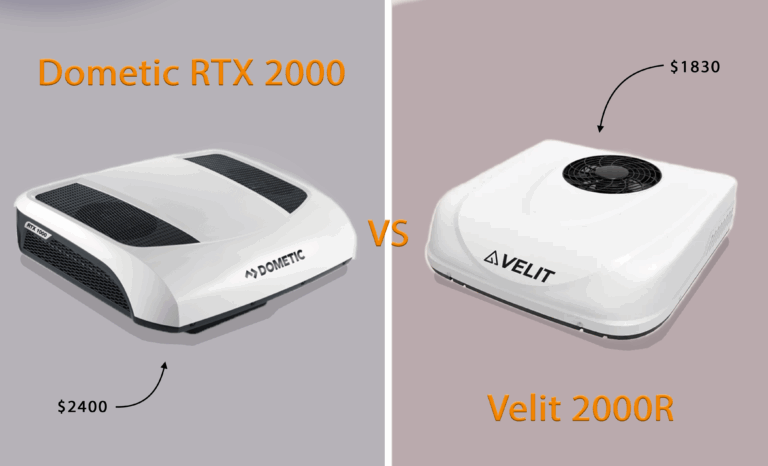

👉 Buying an AC unit? Check out our Velit 2000R vs Dometic RTX2000 Comparison.

For these reasons, a good closed-cell foam is going to be crucial for any Sprinter van conversion or RV repair. Understanding the difference between the different kinds of foam can be very confusing and lead you to make wrong decisions, like I did.

When I installed my roof rails, I read about using neoprene rubber foam between the rails and van to waterproof it and dampen vibrations. I made the mistake purchasing regular neoprene rubber instead of the foam version. It provided very little waterproofing and the hard material damaged the roof paint- do not make that same mistake!

After reading the Ultimate Guide to Closed-Cell Foam for Sprinter Van Builds, you are going to have a PHD in closed-cell foam and make the best decisions for your Sprinter van conversion or RV repair. Let’s dive into it!

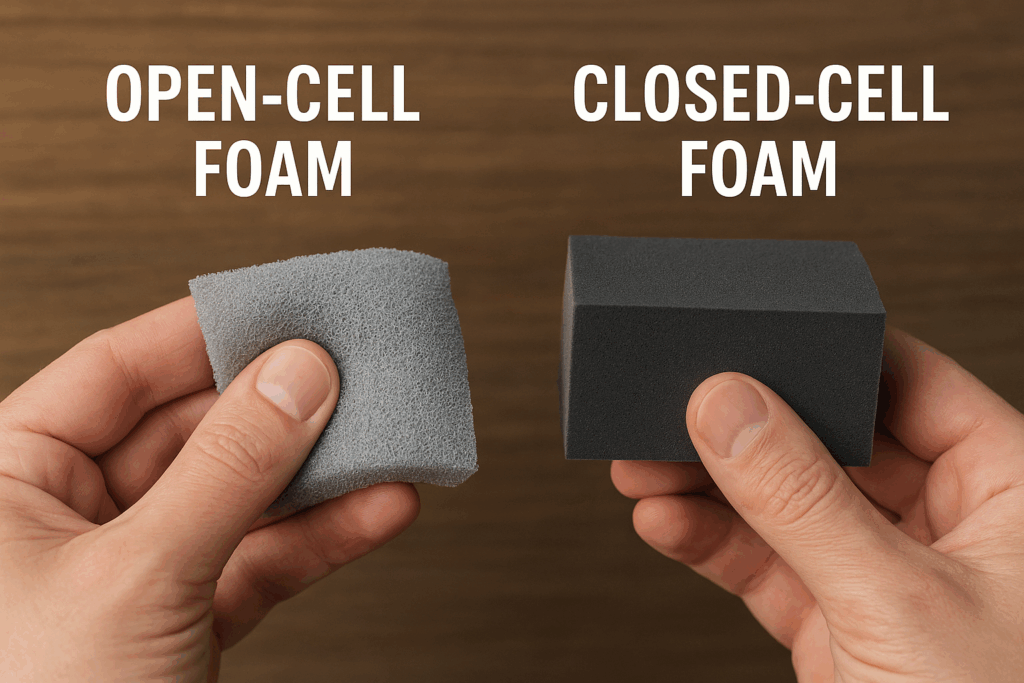

Closed-Cell vs Open-Cell Foam: Know the Difference

Closed-cell foam

Made by mixing plastic or rubber with a gas under high pressure. When the pressure is released, the gas expands to form tiny bubbles, which remain sealed off individually, creating a dense foam.

Open-cell foam

Made similarly, but the chemical mixture and expansion process allow the bubbles to burst and connect, creating an interconnected network of air pockets, resulting in a softer, sponge-like foam.

When you look at any type of foam, it appears to be made of a bunch of small bubbles. In closed- cell foam, none of the bubbles connect. This gives it desirable properties like increased strength, water-resistance, and R-value.

🔒 Bottom Line: Only use closed-cell foam in van builds.

| Property | Closed-Cell Foam | Open-Cell Foam |

|---|---|---|

| Structure | Sealed cells | Interconnected cells |

| Water Resistance | ✅ Excellent | ❌ Poor |

| Strength | ✅ High | ❌ Low |

| R-Value | ✅ Higher | ❌ Lower |

| Ideal Applications | External, structural | Indoor soundproofing |

Best Closed-Cell Foams for External Van Applications

🔻 Tier 3: Basic – Low cost, limited weather resistance

Polyethylene (PE) Foam – Low-cost closed-cell foam, lightweight, water-resistant, good for basic padding and internal cushioning. Poor UV resistance; not good for long-term exterior sealing or weather-exposed areas.

PVC Foam – Inexpensive, often used in window or temporary seals. Moderate flexibility and water resistance, but prone to cracking and deteriorating quickly under UV and weather exposure.

🔸 Tier 2: Good – Weather-capable, affordable

Neoprene Foam – Synthetic rubber with strong water, oil, and weather resistance. Flexible, durable, and reliable for outdoor seals, gaskets under roof rails, or vibration damping. Great general-purpose choice for external van applications.

EPDM Foam – Excellent UV, ozone, and weather resistance, ideal for external seals, roof rail gaskets, and weatherstripping. Slightly less oil-resistant than neoprene, but generally superior in harsh sunlight or long-term outdoor applications.

🟢 Tier 1: Harsh weather, high longevity, pricey

Silicone Foam – Extremely durable, handles extreme temperatures (hot and cold), exceptional UV resistance. Used in critical sealing applications needing long lifespan and reliability (e.g., rooftop equipment, permanent seals). Higher cost.

Vitron Foam – Specialized foam for chemical, oil, and fuel resistance, typically reserved for extreme environments (industrial, automotive, aerospace). Rarely needed in typical van builds; highest cost.

Ranking Closed-Cell Foams for Sprinter Vans

🥇 EPDM Rubber Foam (Closed-Cell)

- Best overall for UV, ozone, and weather resistance

- Ideal under roof rails, AC units, fans, solar mounts

- Long lifespan in sun and rain

- Available adhesive-backed

Go-to material for weatherproof gasketing outdoors.

🥈 Neoprene Rubber Foam (Closed-Cell)

- Slightly less UV resistant than EPDM but more oil/fuel resistant

- Great for mounting pads, vibration isolation, and under rail compression

- Easier to source, more flexible than EPDM

Use when oil/fuel resistance or flexibility is key.

🥉 Silicone Foam (Closed-Cell)

- Premium, long-life material: excellent UV, ozone, and extreme temp resistance

- Ideal for permanent installs or extreme environments

- Downsides: high cost, not as tear-resistant, harder to bond

Use in harsh climates or where longevity is critical.

Important Buying Tips: Foam Density and Thickness

There are variations even within the same material. One thing you will want to take note of is the material density. Density is a measure of the amount of stuff in a given volume ( lb/ft3). We will generally want a medium or high-density version of the foam. This is because higher-density translates to higher compression strength, durability, and water absorption resistance.

Some online sellers do not list the density rating of the foam which is annoying. You can specifically search for “high density foam” or reach out to the seller before purchasing.

You also want to make sure you have the right thickness of foam. You can get very technical with it but the basic is that you want it to be thick enough that it does not fully compress and it can conform to minor surface variations.

Final Thoughts

Using the right closed-cell foam can dramatically improve your van conversion project by preventing leaks, reducing vibrations, and prolonging the lifespan of your installations. Choose wisely and avoid costly mistakes!

If you found this guide helpful, please subscribe to our YouTube channel for more expert van conversion tips.